Tubular Cable Lugs more commonly used than the DIN compression cable lugs are the so-called standard tubular cable lugs. These are also made from electrolytic copper and are offered by various manufacturers. Tubular cable lugs have different dimensions and lengths to DIN cable lugs – as a rule, they are shorter than DIN compression cable lugs and have different tube dimensions.

However, the shorter tube has no negative impact on the durability of the electrical and mechanical connection. Due to the modified tube dimensions, it is not generally possible to process all conductor classes to DIN EN 60228. With hexagonal crimping, only multi-stranded conductors can usually be processed with the tubular cable lug. This is down to the properties of fine-stranded conductors. With indent-like crimp profiles, it is also possible to crimp fine-stranded conductors. Other crimp profiles can be used, and these will be described in more detail in the chapter called “Crimp profiles at a glance”. Multi-stranded, sector-shaped conductors can, of course, also be processed in these cable lugs. This requires the conductor to be pre-rounded with the appropriate sleeves and round crimping dies. Unlike DIN compression cable lugs, the advantage of the tubular cable lug lies in the manufacturing costs. Less copper is required for tubular cable lugs, and this is reflected in the procurement costs.

Unlike DIN compression cable lugs, tubular cable lugs have no crimp markings due to the various crimp profiles. The required number of crimps can be obtained from the relevant manufacturer. With Hanrro, you can find the required number of crimps in the technical appendix in the catalogue, for example. Of course, the tubular cable lug is also available as 45° and 90° angled versions and as connectors with the same properties in processing.

Add to favorites

Add to favorites

Your favorite posts saved to your browsers cookies. If you clear cookies also favorite posts will be deleted.

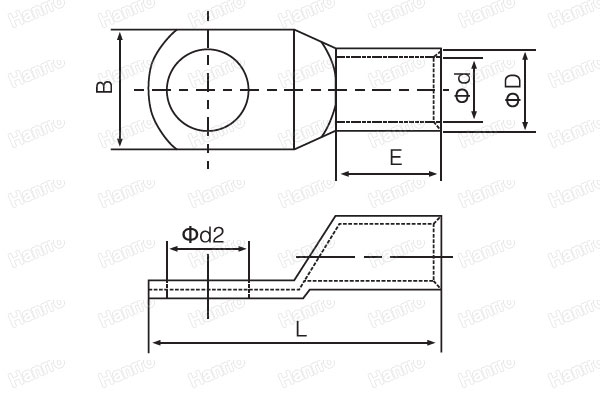

| Item No | Dimension | |||||

| Φ d2 | B | L | Φ D | Φ d | E | |

| KL1-6-5 | 5.5 | 10 | 27.5 | 6.5 | 3.5 | 9 |

| KL1-6-6 | 6.5 | 12 | 27.5 | |||

| KL1-6-8 | 8.4 | 15 | 33 | |||

| KL1-6-10 | 10.5 | 17 | 37 | |||

| KL1-6-12 | 13 | 19 | 41 | |||

| KL1-10-5 | 5.5 | 12 | 28.5 | 7 | 4.6 | 10 |

| KL1-10-6 | 6.5 | 12 | 28.5 | |||

| KL1-10-8 | 8.4 | 15 | 35 | |||

| KL1-10-10 | 10.5 | 17 | 39 | |||

| KL1-10-12 | 13 | 19 | 42 | |||

| KL1-16-5 | 5.5 | 12 | 31.5 | 8.5 | 5.5 | 13 |

| KL1-16-6 | 6.5 | 12 | 33.3 | |||

| KL1-16-8 | 8.4 | 15 | 37.5 | |||

| KL1-16-10 | 10.5 | 17 | 41.5 | |||

| KL1-16-12 | 13 | 19 | 45 | |||

| KL1-25-5 | 5.5 | 14 | 37.5 | 10 | 7 | 15 |

| KL1-25-6 | 6.5 | 14 | 37.5 | |||

| KL1-25-8 | 8.4 | 16 | 42 | |||

| KL1-25-10 | 10.5 | 18 | 46 | |||

| KL1-25-12 | 13 | 19 | 48 | |||

| KL1-25-14 | 15 | 21 | 52.5 | |||

| KL1-35-6 | 6.5 | 17 | 39.5 | 12 | 8.5 | 17 |

| KL1-35-8 | 8.4 | 17 | 44 | |||

| KL1-35-10 | 10.5 | 19 | 49 | |||

| KL1-35-12 | 13 | 21 | 51 | |||

| KL1-35-14 | 15 | 21 | 54.5 | |||

| KL1-35-16 | 17 | 26 | 58 | |||

| KL1-50-6 | 6.5 | 20 | 47 | 14 | 10 | 19 |

| KL1-50-8 | 8.4 | 20 | 47 | |||

| KL1-50-10 | 10.5 | 20 | 51 | |||

| KL1-50-12 | 13 | 23 | 56 | |||

| KL1-50-14 | 15 | 23 | 59.5 | |||

| KL1-50-16 | 17 | 28 | 62 | |||

| KL1-50-20 | 21 | 30 | 67 | |||

| KL1-70-6 | 6.5 | 23 | 53 | 16.5 | 12 | 21 |

| KL1-70-8 | 8.4 | 23 | 53 | |||

| KL1-70-10 | 10.5 | 23 | 56 | |||

| KL1-70-12 | 13 | 23 | 59 | |||

| KL1-70-14 | 15 | 23 | 62.5 | |||

| KL1-70-16 | 17 | 28 | 66 | |||

| KL1-70-20 | 21 | 30 | 72 | |||

| KL1-95-8 | 8.4 | 26 | 60 | 18 | 13.5 | 25 |

| KL1-95-10 | 10.5 | 26 | 60 | |||

| KL1-95-12 | 13 | 26 | 62 | |||

| KL1-95-14 | 15 | 26 | 65.5 | |||

| KL1-95-16 | 17 | 28 | 70 | |||

| KL1-95-20 | 21 | 36 | 82 | |||

| KL1-120-8 | 8.4 | 28 | 65 | 19.5 | 15 | 26 |

| KL1-120-10 | 10.5 | 28 | 65 | |||

| KL1-120-12 | 13 | 28 | 65 | |||

| KL1-120-14 | 15 | 28 | 67 | |||

| KL1-120-16 | 17 | 30 | 70 | |||

| KL1-120-20 | 21 | 36 | 85 | |||

| KL1-150-8 | 8.4 | 31 | 70 | 21 | 16.5 | 30 |

| KL1-150-10 | 10.5 | 31 | 70 | |||

| KL1-150-12 | 13 | 31 | 72 | |||

| KL1-150-14 | 15 | 31 | 72 | |||

| KL1-150-16 | 17 | 31 | 74 | |||

| KL1-150-20 | 21 | 36 | 88 | |||

| KL1-185-10 | 10.5 | 35 | 83 | 24 | 19 | 30 |

| KL1-185-12 | 13 | 35 | 83 | |||

| KL1-185-14 | 15 | 35 | 83 | |||

| KL1-185-16 | 17 | 35 | 83 | |||

| KL1-185-20 | 21 | 39 | 91 | |||

| KL1-240-10 | 10.5 | 39 | 93.5 | 26 | 21 | 35 |

| KL1-240-12 | 13 | 39 | 93.5 | |||

| KL1-240-14 | 15 | 39 | 93.5 | |||

| KL1-240-16 | 17 | 39 | 93.5 | |||

| KL1-240-20 | 21 | 39 | 93.5 | |||

| KL1-300-12 | 13 | 43 | 111 | 29.5 | 23.5 | 44 |

| KL1-300-14 | 15 | 43 | 111 | |||

| KL1-300-16 | 17 | 43 | 111 | |||

| KL1-300-20 | 21 | 43 | 111 | |||

| KL1-400-12 | 13 | 49 | 114 | 34 | 27 | 44 |

| KL1-400-14 | 15 | 49 | 114 | |||

| KL1-400-16 | 17 | 49 | 114 | |||

| KL1-400-20 | 21 | 49 | 114 | |||

Contact Form

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.

Contact

Contact CN

CN