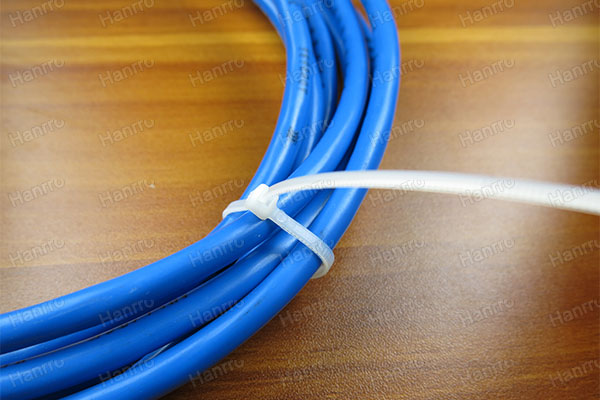

How to choose suitable cable ties

Cable Ties (also known as Zip Ties, Tie Wraps are a type of fastener, for holding and bundling items together, especially for wire & cable. Because of their low cost and ease of use, cable ties are ubiquitous, finding use in a wide range of other applications such as mechanical and electrical applications. In Market , There are many manufactures and many different types , How could you choose the suitable cable ties for your application ? Here is the steps for your reference

Materials

Normally , There will be Polyamide 6.6 (Nylon ) & Stainless Steel

Polyamide 6.6

Polyamide 6.6 ( Glass-Fibre Reinforced ) : PA66GF13 or PA66GF15

Polyamide 6.6 ( Heat and UV Stabilised) : PA66HSW

Polyamide 6.6 ( Heat Stabilised) : PA66HS

Polyamide 6.6 (High Impact Modified , eat and UV Stabilised) : PA66HIR

Polyamide 6.6 ( with metal particles) : PA66MP

Difference Material suitable for different application

Stainless Steel :

201 Grade

Type 201 is specified by some municipalities and utilities initially for lower cost, but also now for its higher strength. Type 201 stainless steel is most often used for attaching signs and electrical fixtures to utility poles, clamping fittings to large diameter hoses and bundling cables and hoses.

304 Grade

Type 304 is a general-purpose stainless steel, most commonly used around the world. If you have any stainless steel appliances (or faucets) it is probably made from type 304. Type 304 stainless steel is widely used in the sign and electrical industries to name a few. From our experience: Some of the most common uses are strapping insulation jacketing to pipes and tanks; fixing lightweight signs and advertising materials to columns or posts. In the pipelines, type 304 stainless steel banding is used to strap heat tracer cables to pipelines to prevent freezing.

316 Grade

Type 316 was developed for added corrosion resistance. It generally has a slightly higher nickel content, but is distinguished by the addition of molybdenum (Mb). This Type of stainless steel is specified and used in marine environments; e.g. ocean going ships and oil and gas drilling platforms. From our experience, it’s typically used to fix cables to cable trays or columns and bundling cables or hoses. Type 316 banding is very common along coastlines (for signs or decorations), or in refrigeration applications

316L Grade

317 Grade Etc

Application

Cable Ties have different types for different application , In Market There will be following :

Self-Locking Cable Ties : can be used in countless applications ,One-piece construction for consistent performance and reliability

UV Resistant Cable Ties : suitable for outdoor applications.Ideal for use outside, even in the most demanding conditions

Releasable Cable Ties : perfect solution for any wire and cable bundling needs that may require changes in the future

Heat Stabilized Cable Ties : used in continuous or extended exposure to high temperatures (up to 250°F) and meet UL standards for electrical applications

Mounted Head Cable Ties :effective for use in a wide variety of cable and wire bundling applications that Require that a wire or cable bundle be attached to another surface such as a control panel, wall, or ceiling.

Metal Detectable Cable Ties : use in the food and pharmaceutical processing industries. A unique manufacturing process , involving the inclusion of a metallic pigment , enables even small cut-off sections of the ties to be detected by standard metal detecting equipment

Tefzel Cable Ties : ideal for providing high resistance to environmental stresses such as chemical attack, gamma radiation, ultraviolet radiation and extreme temperatures

Reel Fed Cable Ties : use specifically in the automatic cable tying systems. The Hellermanntyton or Panduit Autotool 2000 CPK & Machine is ideally suited for handling high volumes applications in wire harness facilities, automotive and industrial companies as wells as the packaging sector.

Sizes/Strengths

If you have ever purchased cable ties, you know that they are available in many lengths and widths. This, however, does not necessarily correspond to strength rating. All of these ties are rated by a loop tensile strength or LTS, which is stated in pounds. The most common ties range between 18 lb and 175 lb.

The LTS is the maximum amount of force that can be exerted on the locking mechanism once it has been deployed.

Maximum Diameter

This refers to the largest diameter of the bundle to be tied or restrained.

Length & Width

The cable tie should fit around the bundle and the loose end pulled completely through the locking device. As long as the tie fits the bundle and can be locked securely, it’s all good. Longer ties can be used to secure items, such as cargo or merchandise.

Temperature Range

Consider the operating conditions inherent to the intended application. Will the tie be utilized inside or outside? Will there be any extreme cold or heat that will affect the cable tie? Keep in mind that cold temperatures can cause most nonmetallic materials to brittle.

Here at Hanrro, we are always ready to assist you in finding the perfect cable tie for the job. Give us a call !

Contact

Contact CN

CN