Metric Butt Splices are actually a fairly common and useful connector used in electrical work. Metric Butt Splices are a form of so called “crimp” connectors. Crimp connectors are used to terminate wires safely, or connect one wire to another. The wire is inserted into the connector. Then the connector is “crimped”, usually with pliers. As a result, the connector is bent and deformed around the wire. This crimping forces the wire into contact with the metal inside the connector. The other end can either be crimped to terminate the wire. Alternatively the process can be repeated on the other side, with another wire, to connect two wires. The metric butt splice connector is simply a cylindrical crimp connector with one crimp on each end. Some butt splice connectors are manufactured with heat shrinking ends which contract around the wire when exposed to heat, leading to a better seal between the wire and butt splice connector.convenient, easy to use

Given its simple design and purpose, why should you use a metric butt splices ? Typically, crimp connectors and soldering are two common methods of connecting wires. For many applications, the butt splice connector holds considerable advantages over soldering. Butt splice connectors are cheap and easy to use. Soldering equipment takes much longer to set up and use. Butt splice connectors are also safer than soldering equipment, with no heat and no toxins. Overall, the butt splice connector is a great connector to have. It is safe, convenient, easy to use, and cheap.

Features & Benefits :

Internal wire stops to prevent over-insertion of conductor

Tin-Plated to inhibit corrosion

UL Listed and CSA Certified to 35 KV and Temperature rated to 90℃ when crimped with Hanrro and Specified competitor crimping tools and dies

UL Listed and CSA Certified for wide wire range taking

Tested by Telcordia-meets NEBS Level 3

Add to favorites

Add to favorites

Your favorite posts saved to your browsers cookies. If you clear cookies also favorite posts will be deleted.

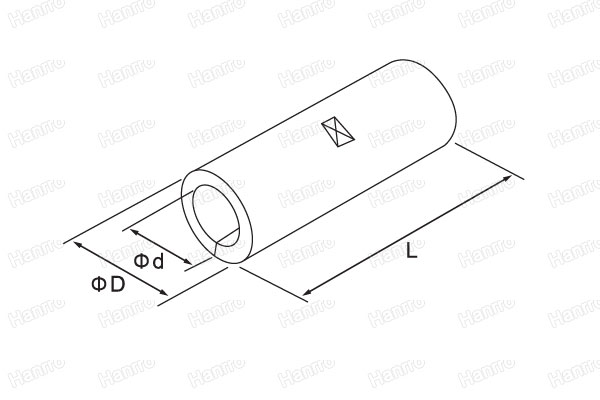

| Item No | Dimension | ||

| L | Φ D | Φ d | |

| M1.5 | 22 | 4.0 | 2.4 |

| M2.5 | 22 | 4.3 | 2.7 |

| M4 | 25 | 4.8 | 3.1 |

| M6 | 25 | 5.5 | 3.8 |

| M10 | 25 | 6.9 | 4.7 |

| M16 | 29 | 7.8 | 5.6 |

| M25 | 29 | 9.5 | 7.1 |

| M35 | 35 | 11.0 | 8.2 |

| M40 | 35 | 11.2 | 9 |

| M50 | 35 | 12.5 | 9.5 |

| M70 | 45 | 15.0 | 11.5 |

| M95 | 47 | 17.0 | 13.5 |

| M120 | 52 | 20.0 | 15.6 |

| M150 | 59 | 21.0 | 16.5 |

| M185 | 65 | 23.6 | 18.4 |

| M240 | 75 | 26.4 | 21.2 |

| M300 | 90 | 28.6 | 23.4 |

| M400 | 106 | 32.8 | 26.8 |

| S-M1.5 | 15 | 3.3 | 1.8 |

| S-M2.5 | 15 | 4.3 | 2.7 |

| S-M4 | 22 | 5 | 3.3 |

| S-M6 | 22 | 5.5 | 3.8 |

| S-M10 | 25 | 6.8 | 4.7 |

| S-M16 | 27 | 7.8 | 5.6 |

| S-M25 | 29 | 9.4 | 7.1 |

| S-M35 | 33 | 11.3 | 8.7 |

| S-M50 | 35 | 12.6 | 9.8 |

| S-M70 | 39 | 14.7 | 11.5 |

| S-M95 | 43 | 16.9 | 13.5 |

| S-M120 | 47 | 19.9 | 15.6 |

| S-M150 | 58 | 20.9 | 16.5 |

| S-M185 | 64 | 23.7 | 18.8 |

| S-M240 | 75 | 26.2 | 21.2 |

| S-M300 | 90 | 28.6 | 23.4 |

| S-M400 | 90 | 32.8 | 26.8 |

Contact Form

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.

Contact

Contact CN

CN