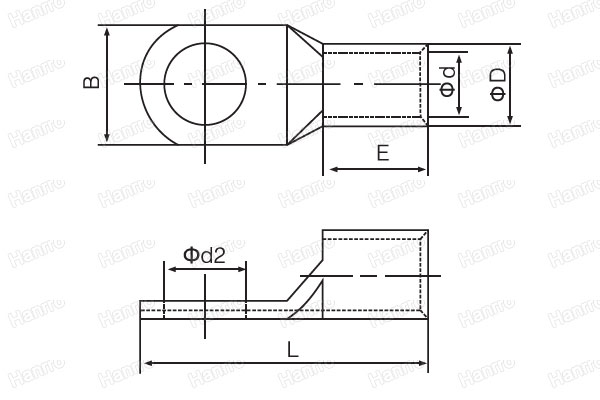

SC Copper Cable Lug are made by high conductivity copper which used for code conductors One-Hole with Inspection Window Design. Seamless tubular barrel provides a consistent high performance quality crimp.

Round double thick tongue for reliable power application. And Barrel of terminal internally beveled to provide quick and easy wire insertion.

SC Copper Cable Lugs Surface Treatment by Tin-Plated to inhibit corrosion

Contact

Contact CN

CN