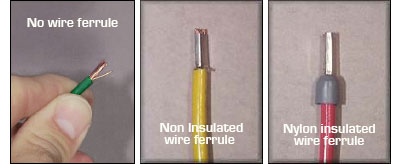

Insulated Wire Ferrules is to prevent the wires from fraying or fanning out, which is a common problem when using stranded wire. Wire ferrules are cylindrical in shape and made of a tin plated copper. They are available with a nylon extruded jacket or non insulated.

In the first picture you can see a single strand of wire that has separated from the group of stranded wires. Occasionally this can happen during the installation process. This loose strand can cause a possible intermittent failure in the electrical system and these types of failures are more difficult to locate and can be very expensive to isolate and repair. Using a wire ferrule can turn a stranded wire with into a solid wire, which will in the end save you time & money.

Insulated Wire Ferrules can also ensure that you get 100% conductivity when inserting your terminated wire into the connection you are working with. For example- a terminal block or trailer receptacle and plug with pressure plated setscrews.

For Non Insulated , Please visit : Non Insulated Wire Ferrules

For Twin Entry , Please visit : Twin Entry Wire Ferrules

For Nylon , Please visit : Nylon Insulated Cord End Terminals

For Dual Entry , Please visit : Dual Entry Cord End Terminals

Contact

Contact CN

CN